Molybdenum Diamond & Ruby Wire Guide for Medium Speed Wire Cut Machine

Description

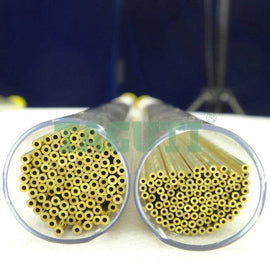

TAGUTI wire guides for molybdenum wire EDM machines adopt two different structures of ruby + diamond (ceramic + diamond) and ruby. They can effectively control the molybdenum vibration caused by the molybdenum wire during high-speed reciprocating operation, thereby significantly improving the surface finish and accuracy of the processed workpiece.

The red surface of the wire guide is made of ruby (the white one is made of ceramic). Ruby and ceramic mainly serve to insulate and hold the diamond inside, and there is no difference in quality.

Inlaid inside the ruby (ceramic) is an artificial diamond with a thickness over 1.2mm and a hardness of about 9.8 (Mohs hardness standard). It is very hard and wear-resistant. The incoming chamfers and outgoing chamfers are ground by hand so that the molybdenum wire can passes through the wire guide very smoothly. It is suitable for use in scenarios where the machining taper is within three degrees.